Offer

1. ROTATIONAL MOULDING

Rotomoulding, or rotational moulding, is our speciality. We use the latest technology to create products with high strength and precision. Using this method, we can produce both small and large batches of parts in a variety of shapes and sizes. Our solutions are used in many industries, including horticulture, automotive and leisure.

Key advantages of rotational moulding:

- Low mould manufacturing costs

- Ability to produce large parts

- High quality and durability of products

- Flexibility to produce small and large series

2. DESIGN AND MANUFACTURE OF MOULD

We provide a full range of mould design and manufacturing services. Our experienced team of engineers work with clients to create moulds that meet the highest standards. From the initial consultation, to the creation of 3D models, to the production and testing of moulds, we take care of every step of the process to ensure maximum precision and quality.

The design process includes:

- Consultation and analysis of customer needs

- Creation of 3D models and prototypes

- Production of moulds using the latest technology

- Testing and optimisation of the mould before production begins

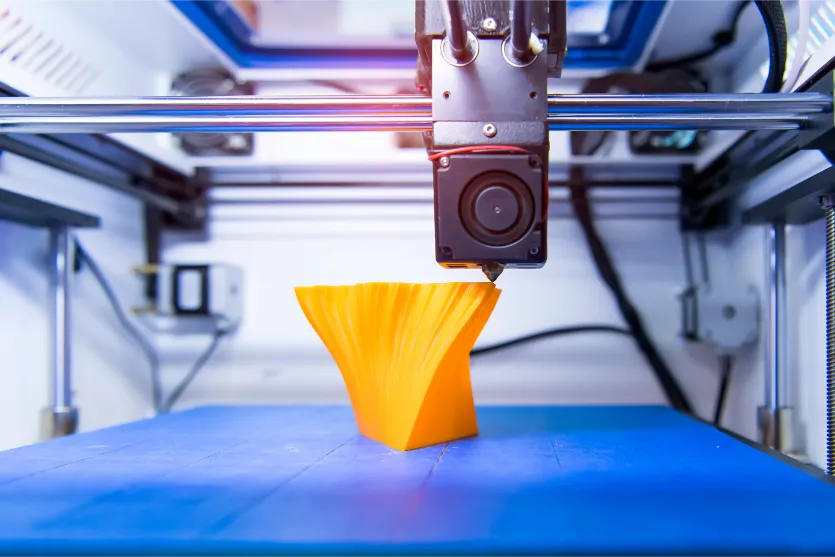

3. 3D PRINTING

We use 3D printing for prototyping and small batch production. This technology allows projects to be realised quickly and precisely, reducing time to market. 3D printing enables even the most complex shapes and geometries to be realised, while ensuring high quality and durability.

Our 3D printing services include:

- Creating functional prototypes

- Production of components with complex geometries

- Rapid design iterations

- Materials with high strength and a variety of properties

4. POST-PROCESSING AND ASSEMBLY OF CUSTOMER COMPONENTS

We offer a full range of post-processing and assembly services, providing ready-to-use products of the highest quality. Our advanced technologies and experienced team guarantee precise finishing and professional assembly of components.

Our capabilities include:

- Finishing: grinding, polishing, painting

- Assembly of finished components

- Quality and functionality testing

- Packaging and preparation for dispatch

Our mission is to provide technologically advanced products that meet the requirements of our customers. Thanks to modern production methods, we guarantee the durability and reliability of our products.

Do you have questions? Get in touch with our team of experts. We will be happy to advise and help you with your project from concept to final product.